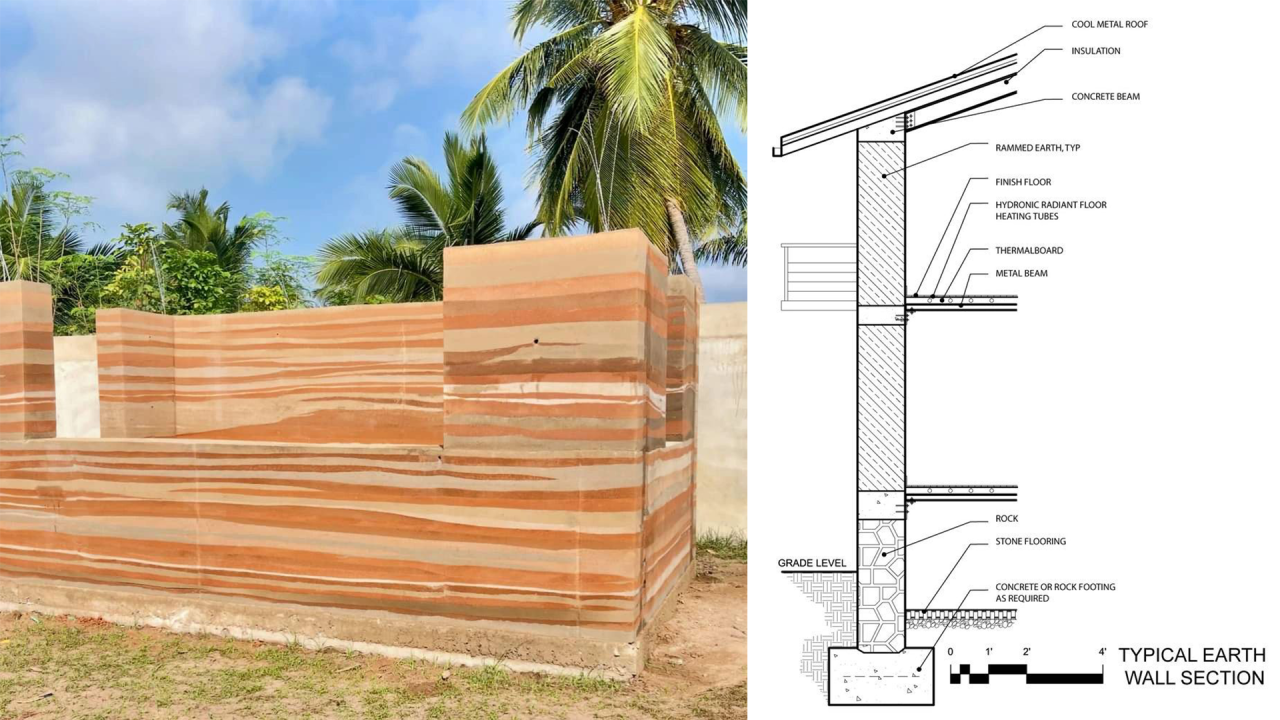

What is Rammed Earth Construction?

Rammed Earth is a form of building technology which involves compacting a damp mixture of local soils that have suitable properties of sand, gravel, clay, silt, and a soil stabilizer (lime/cement) into a formwork to produce a high-density stone-like wall.

Mixture:

The subsoil composition is as follows: clay (15-25%), sand (50-60%) and gravel (15-20%) with or with out a small percentage of stabilizers such as lime powder (7-10%) and minimum water of (8-12%)

Formwork and Moulding:

The soil gets tamped between shutters with manual or pneumatic rammers. The shuttering is best designed so that a whole wall can be built on one go, thus eliminating joints that would cause cracks with in panels as much as possible.

The formwork/shuttering system comprises of end panels which can be quickly assembled and disassembled to provide end stops to support side panels without the need for through-ties. The end panels comprise integral handholds for access to the full height of the formwork. The end panels are stackable, rotatable and interchangeable, such that one set of formwork may be used to create several different wall configurations. The finished wall contains an internal support structure and insulating core, without through-holes.

Rammed earth walls are limited to the shapes that can be built with removable shuttering and left as they are, with the natural looking strata pattern from the ramming process.

Consistent workmanship is critical for both the appearance and strength of the rammed earth walls, therefore site works have to be of high quality. An area of wall that is not mixed or rammed correctly can ruin a whole panel.

Compressive Strength:

Too much clay in the soil increase its compressibility while too little prevents it from binding. That is why in some cases stabilization materials are added like little percentage of cement or lime powder.

Maximum compressive strength is achieved by ensuring that there is maximum dry density in the mix and proper formwork along with accurate ramming procedures are also key.

The average compressive strength should not be less than 1.5 N/mm2 generally or 2.0 N/mm2 for walls of height between 3.0 m and 6.0 m at a minimum age of 7 days of curing.

Durability:

Basically ability of the materials/structure to maintain its functionality over time and in this case its about resistance against water-induced erosion that weaken it overtime.

There are different decay mechanisms such as shrinkage, surface erosion, sacrificial erosion, freeze/thaw cycles, organic growth, delamination and dampness.

Shrinkage is the most common as it leads to cracking and sorted by adding sandy/gravelly materials.

Common Quality Tests:

- Drop test – Checks the optimum moisture content in the sample mixture.

In this case, you take a sample of damp mix from the larger mixture and squeeze it into a ball of 40 mm diameter in between hands.

Stretch out you arm to shoulder level at a height of 1.5m ,with a piece of plywood(or any other soft wood) right below, drop it.

If the mix remains intact, it shows its too wet so let it dry and try again.

If the mix breaks into many pieces, it shows its too dry hence add water and try again.

If the mix breaks into lesser pieces, it shows its too dry hence add water and try again.

- Roll test – Checks the the clay content in the mixture as its key in cohesion.

In this case, you take a sample of damp mix from the larger mixture and squeeze it into a rod size 25 mm diameter and 200 mm long in between hands.

Place the roll on a table and push it gently over the edge to check how longer it gets before it breaks off and consequently the length of the piece that drops off.

If the roll breaks off less than 80 mm, there is not enough clay. If the roll breaks off longer than 120 mm, there is too much clay.

Benefits:

- Thermal comfort – They can absorb heat during the day and release it slowly at night. This helps regulate indoor temperatures, providing a naturally comfortable living environment with less reliance on heating and cooling systems.

- Sustainable – Construction generates minimal waste, as most materials come from the site itself. It also has low embodied energy compared to conventional materials like concrete making it environmentally friendly.

- Natural aesthetics – The natural colors and textures of rammed earth formed from the layering process create a unique, earthy look that blends harmoniously with the environment. The unique walls create a warm, organic feel.

- Affordable – Earth is an abundant thus making rammed earth buildings are very economical. The construction method is seamless, with unskilled labor intensity.

ammed earth is a frontier in the generation of low cost sustainable housing in developing countries for both in our rural and urban areas..

Very popular in West Africa and Ghana in particular. In East Africa, Uganda are leading the way followed closely by Tanzania (Zanzibar) and Rwanda.We are in the process of popularizing it in Kenya.

Context is crucial in architecture. Designs must respond to their surroundings and respect the local culture.

For more information, reach out to us via info@rickfes.co.ke

At Rickfes Construction Ltd., We are exploring earth-based technologies such as Rammed Earth and Interlocking Stabilized Soil Blocks (ISSB). These methods reduce material waste, lower carbon footprints, and make quality housing accessible, particularly in marginalized and rural communities.